Published: Sep 15, 2025

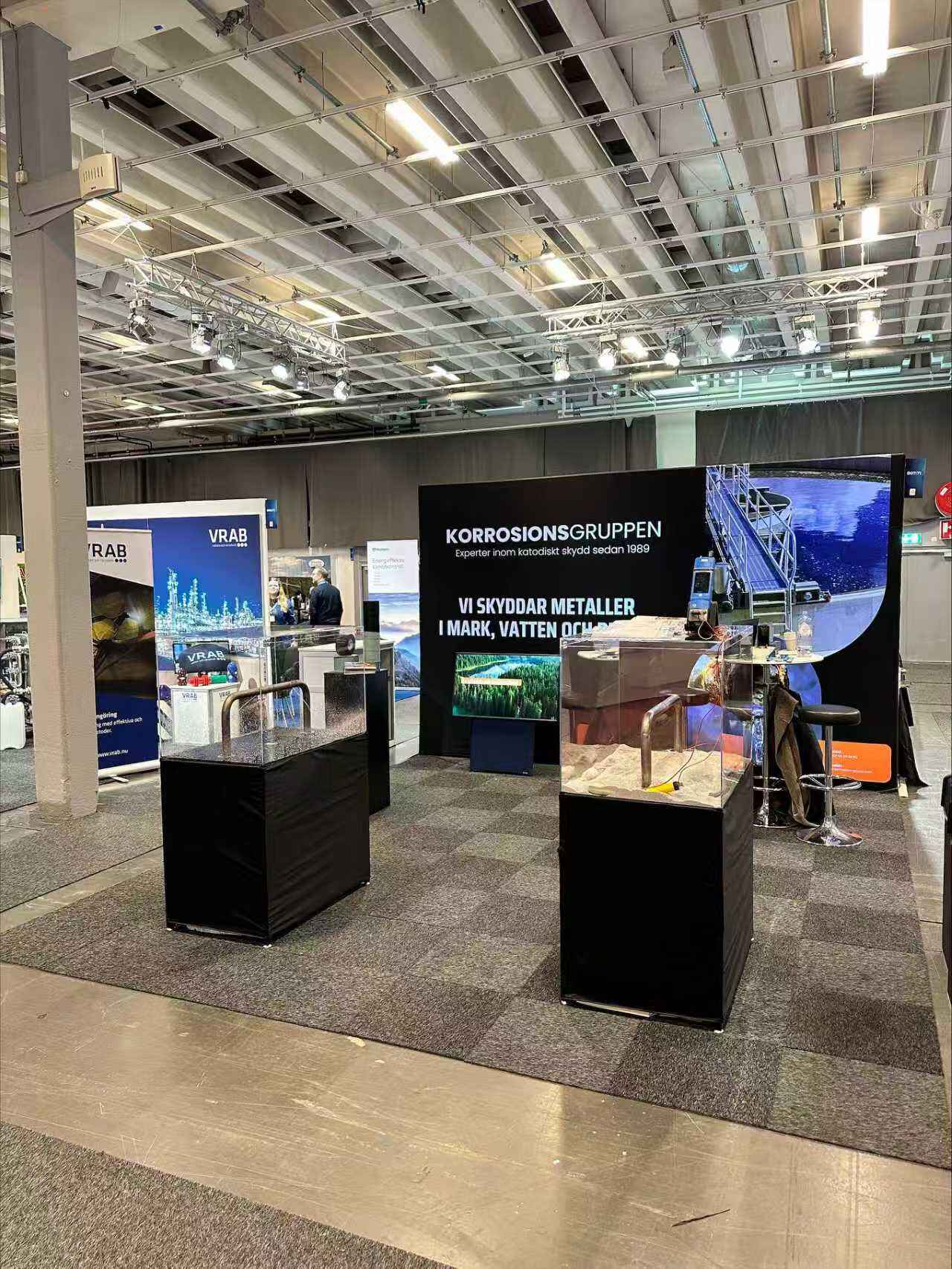

For industrial brands like Korrosionsgruppen (a Scandinavia-leading corrosion protection expert established in 1989), standing out at bustling trade shows while effectively showcasing technical, material-focused solutions demands displays that balance strategic functionality, consistent brand identity, and on-site adaptability. This custom exhibit stand—featured at the 2025 Nordic Industrial Materials Expo—masters this balance: it transforms how the brand presents its corrosion-resistant technologies, engages industry attendees, and maximizes expo floor impact. Here’s a deep dive into its value across core dimensions:

Brand-Aligned Design: Turning Displays Into Brand Ambassadors

The stand is engineered to embed Korrosionsgruppen’s brand identity into every visual and tactile touchpoint:

• It leans into the brand’s signature high-contrast black-and-white color scheme: matte black pedestals and backdrop frames pair with crisp white typography (showcasing the tagline “Vi skyddar metaller i mark, vatten och luft” [We protect metals in soil, water, and air]) to cut through the visual noise of crowded expo halls.

• The large curved LED backdrop (integrated into the stand’s structure) cycles between brand imagery (e.g., the company’s 1989 founding milestone) and real-world application visuals (e.g., corrosion-protected marine infrastructure, underground pipelines)—linking the brand’s legacy to its current technical capabilities.

• The glass-topped display cases (housed in the black pedestals) feature subtle etched brand logos on their edges: a understated detail that reinforces brand recall without distracting from the product samples inside.

Product-Centric Functionality: Optimized for Industrial Demo Success

Tailored specifically to Korrosionsgruppen’s need to showcase physical metal samples and technical solutions, the stand’s functionality is built around clear, interactive demonstration:

• Dual-Tiered Display Cases: Each black pedestal includes a two-level storage and display system:

○ The top layer uses a 10mm tempered glass enclosure (with a hinged, lockable lid) to protect high-value metal samples (e.g., corrosion-treated steel components exposed to saltwater for 12+ months) while keeping them fully visible. The glass is anti-glare coated—ensuring attendees can inspect surface textures even under harsh expo lighting.

○ The lower layer (a hidden pull-out drawer with foam inserts) stores supplementary materials: product spec sheets, small-scale test kits, and branded magnifying glasses (for close inspection of corrosion-resistant coatings). This keeps demo tools organized and easily accessible, without cluttering the demo zone.

• Side-by-Side Comparison Zones: The two-pedestal layout is intentionally spaced to enable direct, head-to-head comparisons: attendees can view an untreated metal sample (showing rust and degradation) on one pedestal, and a Korrosionsgruppen-treated equivalent (preserved after 24 months of outdoor exposure) on the other—turning abstract “corrosion protection” into a tangible, visual difference.

• Integrated Tech Sync: The backdrop screen is connected to a small tablet (stored in the pedestal drawer) that lets staff pull up real-time data (e.g., corrosion resistance test results) to pair with the physical samples—adding depth to demos without requiring bulky equipment.

Space & Flexibility Optimization: Maximizing Compact Expo Footprints

Designed for the constraints of trade show booths (typically 10x10 or 10x20 ft spaces), the stand prioritizes efficiency and adaptability:

• Modular Componentry: Every part of the stand (pedestals, backdrop frame, glass cases) is detachable and stackable. This lets the team reconfigure the layout based on booth size: for smaller events, they can remove one pedestal and condense the backdrop; for larger expos, they can add a third pedestal (compatible with the same frame) to showcase more samples.

• Vertical Space Utilization: The backdrop extends 8 feet high (the maximum allowed by most expo venues) to display brand messaging—turning vertical space into a “billboard” that’s visible from across the hall, without taking up extra floor area.

• Portable Storage: The pedestals double as storage cases for small samples and materials during transit—eliminating the need for separate shipping crates and cutting logistics costs.

Durability: Built for Repeated Industrial Trade Show Use

Industrial trade shows often involve heavy foot traffic, rough handling, and exposure to diverse environments (e.g., humid expo halls, outdoor demo zones). This stand is engineered to last:

• Heavy-Duty Materials: The pedestals are constructed from 16-gauge steel (wrapped in tear-resistant black fabric) that supports up to 50kg per shelf—enough to hold large metal components. The glass cases are shatter-resistant, and the backdrop frame is made from aluminum alloy (rust-proof and lightweight).

• Low-Maintenance Design: The fabric wraps are machine-washable, and the steel components are coated with a scratch-resistant finish—ensuring the stand looks new even after 10+ trade show appearances.

• Long-Term Reusability: Unlike disposable pop-up stands, this display is designed to be updated (e.g., swapping out the backdrop graphic for new product launches) rather than replaced—making it a cost-effective asset for Korrosionsgruppen’s multi-year exhibition strategy.

In short, this custom display stand isn’t just a “place to put samples”—it’s a strategic tool that turns Korrosionsgruppen’s trade show presence into a memorable, brand-driven experience. It bridges technical complexity to tangible customer value, while adapting to the unique demands of industrial events—proving that a well-designed display can be as impactful as the products it showcases.