When businesses consider retail display solutions, durability concerns often arise regarding cardboard display stand options. Despite common misconceptions about paper-based materials, modern cardboard display stands offer surprising strength and longevity when properly designed and manufactured. Understanding the factors that contribute to cardboard display stand durability helps retailers make informed decisions about their merchandising investments.

The retail industry has witnessed significant evolution in cardboard display stand technology over recent decades. Advanced manufacturing techniques and material science innovations have transformed these displays from simple promotional tools into robust merchandising solutions capable of supporting substantial weight loads while maintaining structural integrity throughout extended retail campaigns.

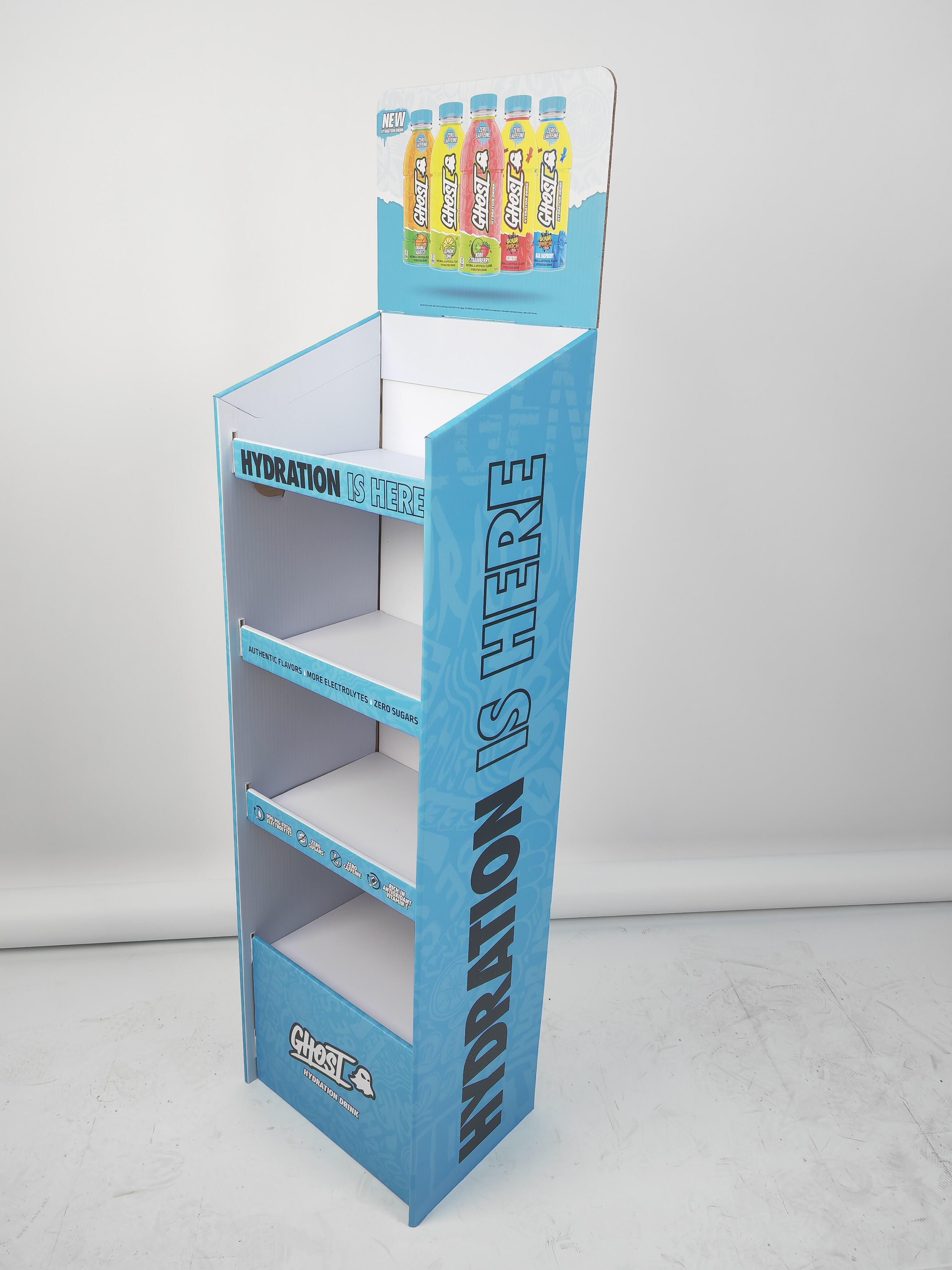

Modern cardboard display stands incorporate engineering principles that maximize strength while minimizing material usage. The corrugated structure provides exceptional rigidity through its fluted design, creating air pockets that distribute weight evenly across the entire framework. This engineering approach allows a well-designed cardboard display stand to support products weighing several hundred pounds when properly assembled.

Material Construction and Engineering Principles

Corrugated Cardboard Composition

The foundation of any durable cardboard display stand lies in its corrugated construction. Multiple layers of kraft paper create a sandwich structure with fluted channels running between flat sheets. This configuration provides remarkable compressive strength while maintaining lightweight characteristics that facilitate easy transportation and assembly.

Edge crush strength represents a critical measurement for cardboard display stand durability. High-quality displays utilize corrugated materials with edge crush values exceeding industry standards, ensuring the structure can withstand vertical compression forces without buckling or failing under load.

Moisture resistance treatments applied during manufacturing enhance the longevity of cardboard display stands in various retail environments. Specialized coatings protect against humidity fluctuations and minor spills that might otherwise compromise structural integrity.

Structural Design Optimization

Engineering principles guide the development of cardboard display stand configurations that maximize load-bearing capacity. Strategic placement of support columns, reinforcement panels, and bracing elements creates a framework capable of distributing weight efficiently throughout the entire structure.

Interlocking assembly systems eliminate the need for adhesives or fasteners while creating secure connections between display components. These mechanical joints maintain their integrity throughout the display lifecycle, ensuring consistent performance even under repeated handling and restocking activities.

Load distribution calculations inform the placement of shelves and product support surfaces within each cardboard display stand design. Proper weight distribution prevents stress concentration points that could lead to premature failure or structural compromise.

Durability Testing and Performance Standards

Industry Testing Protocols

Comprehensive testing procedures evaluate cardboard display stand performance under simulated retail conditions. These assessments include static load testing, dynamic stress evaluation, and environmental exposure studies that verify durability across various operational scenarios.

Compression testing measures the maximum weight capacity of vertical support elements within each cardboard display stand configuration. Results from these evaluations inform load rating specifications and guide proper product placement recommendations for retail implementation.

Fatigue testing simulates repeated loading and unloading cycles that occur during normal retail operations. This evaluation process ensures that cardboard display stands maintain structural integrity throughout extended merchandising campaigns without experiencing degradation or failure.

Environmental Resistance Evaluation

Temperature and humidity fluctuations present ongoing challenges for retail display materials. Cardboard display stand testing includes exposure to varying environmental conditions that replicate typical store environments, ensuring consistent performance across different geographic regions and seasonal variations.

Accelerated aging studies provide insights into long-term cardboard display stand performance characteristics. These evaluations compress months of typical usage into concentrated testing periods, revealing potential weaknesses before products reach retail locations.

Chemical resistance testing evaluates how cardboard display stands respond to common retail environment contaminants. Cleaning products, food spills, and other substances encountered in store settings are assessed to ensure displays maintain their appearance and functionality throughout their intended lifespan.

Factors Affecting Cardboard Display Stand Longevity

Environmental Considerations

Store climate control systems significantly impact cardboard display stand durability. Consistent temperature and humidity levels help maintain material properties and prevent dimensional changes that could compromise structural integrity over time.

Proper placement away from direct sunlight and heat sources preserves the appearance and strength characteristics of cardboard display stands. UV exposure can cause material degradation and color fading that affects both functionality and visual appeal.

Air circulation around display locations prevents moisture accumulation that might weaken cardboard materials. Strategic positioning ensures adequate ventilation while maintaining optimal product visibility and customer accessibility.

Handling and Assembly Practices

Proper assembly techniques maximize the structural performance of cardboard display stands. Following manufacturer instructions ensures all connections achieve their intended strength and that load distribution occurs as designed.

Careful handling during transportation and setup prevents damage to critical structural elements. Training retail staff on proper cardboard display stand handling procedures helps maintain display integrity throughout their operational lifespan.

Regular inspection and maintenance activities identify potential issues before they compromise display performance. Simple preventive measures can significantly extend the useful life of cardboard display stands in retail environments.

Comparative Advantages and Cost Effectiveness

Performance Versus Traditional Materials

When compared to metal or plastic alternatives, modern cardboard display stands offer competitive durability for many retail applications. The weight-to-strength ratio often exceeds that of alternative materials while providing significant cost advantages.

Customization flexibility represents a major advantage of cardboard display stand solutions. Complex shapes and configurations can be achieved through die-cutting and folding techniques that would be prohibitively expensive with traditional materials.

Shipping efficiency contributes to the overall value proposition of cardboard display stands. Flat-pack shipping reduces transportation costs while minimizing storage requirements until deployment.

Environmental and Economic Benefits

Recyclability at end-of-life provides environmental advantages that align with corporate sustainability goals. Cardboard display stands can be processed through existing recycling infrastructure without specialized handling requirements.

Lower material costs enable more frequent display updates and seasonal merchandising campaigns. The economic efficiency of cardboard display stands supports dynamic retail strategies that maintain customer interest and drive sales.

Reduced setup time and minimal tools requirements streamline deployment processes. Store personnel can assemble cardboard display stands quickly without specialized training or equipment, reducing labor costs and operational complexity.

Optimization Strategies for Maximum Durability

Design Considerations

Strategic reinforcement placement enhances cardboard display stand durability without significantly increasing material costs. Additional support elements in high-stress areas prevent premature failure while maintaining cost-effectiveness.

Modular design approaches allow for component replacement if damage occurs. This strategy extends the overall lifespan of cardboard display stand systems while minimizing waste and replacement costs.

Load balancing through careful product placement ensures even stress distribution across all structural elements. Proper merchandising techniques maximize both display stability and product presentation effectiveness.

Maintenance and Care Protocols

Regular cleaning procedures maintain the appearance and functionality of cardboard display stands throughout their service life. Gentle cleaning methods preserve surface treatments while removing accumulated dirt and debris.

Prompt attention to minor damage prevents small issues from developing into major structural problems. Simple repairs using appropriate adhesives or reinforcement materials can significantly extend cardboard display stand longevity.

Documentation of performance metrics helps identify optimization opportunities for future cardboard display stand deployments. Tracking durability data informs design improvements and deployment strategies.

FAQ

How long do cardboard display stands typically last in retail environments

Well-designed cardboard display stands can maintain their structural integrity and appearance for 3-6 months in typical retail environments, with some premium designs lasting up to 12 months depending on usage conditions and maintenance practices. The actual lifespan varies based on factors such as store traffic, product weight, environmental conditions, and handling procedures.

What weight capacity can modern cardboard display stands support safely

Contemporary cardboard display stands engineered with proper reinforcement can safely support between 50-500 pounds depending on their size and configuration. Floor displays typically handle heavier loads than countertop units, with weight distribution being more critical than total weight in determining safe capacity limits.

Are cardboard display stands suitable for outdoor or high-humidity environments

Standard cardboard display stands perform best in controlled indoor environments, but specially treated versions with moisture-resistant coatings can function effectively in moderate humidity conditions. For outdoor applications or high-moisture environments, enhanced treatments or alternative materials may be necessary to maintain structural integrity.

How do cardboard display stands compare cost-wise to metal or plastic alternatives

Cardboard display stands typically cost 40-70% less than comparable metal or plastic displays while offering sufficient durability for short to medium-term promotional campaigns. The lower initial investment allows for more frequent design updates and seasonal merchandising changes, often providing better overall value despite shorter individual unit lifespans.

Table of Contents

- Material Construction and Engineering Principles

- Durability Testing and Performance Standards

- Factors Affecting Cardboard Display Stand Longevity

- Comparative Advantages and Cost Effectiveness

- Optimization Strategies for Maximum Durability

-

FAQ

- How long do cardboard display stands typically last in retail environments

- What weight capacity can modern cardboard display stands support safely

- Are cardboard display stands suitable for outdoor or high-humidity environments

- How do cardboard display stands compare cost-wise to metal or plastic alternatives